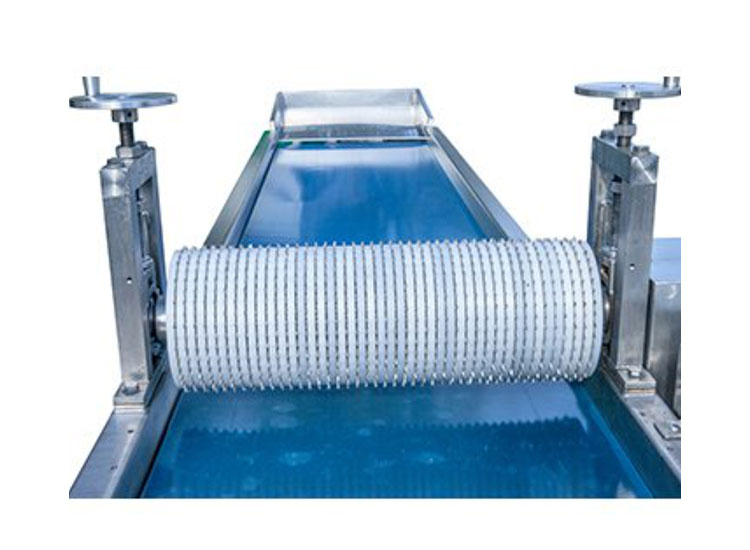

The Spiked Puncturing Machine (or Pinning/Needling Machine) in the food sector is an industrial pre-processing machine used especially during the processing of pickles and certain olive varieties. It gets its name from having numerous small and sharp piercing blades or needles on its surface; this appearance resembles a hedgehog.

- It is used when products such as gherkins (small cucumbers), peppers, or okra are to be fermented or preserved with brine. The punctured surfaces allow the brine water or salt to penetrate the product much faster, more uniformly, and thoroughly.

- This shortens the fermentation time and helps preserve the crisp structure of the pickle, while standardizing its quality.

- Manual puncturing or pinning is a very time-consuming and expensive process. The spiked machine can operate at capacities ranging between 750 kg and 2000 kg per hour.

- Generally, as products advance on a speed-controlled PVC belt inside the machine, they pass over specially designed stainless steel piercing blade/needle rollers, and each product is punctured repeatedly.